Innovative Recycling Techniques for Metals

In the quest for sustainability and environmental preservation, recycling has taken center stage, especially in the metal industry. Metals are indispensable to our modern lifestyle, used in everything from construction and transportation to electronics and packaging. However, the environmental impact of mining and processing virgin metals is significant, prompting a shift towards more innovative recycling techniques. This blog explores the cutting-edge technologies reshaping metal recycling, making it not only more efficient but also a cornerstone of the circular economy.

The Advent of Bioleaching

Imagine harnessing the power of microorganisms to recover precious metals from waste. Bioleaching is a groundbreaking technique that does just that, using bacteria and fungi to extract metals like copper, gold, and zinc from solid waste. This method stands out for its minimal environmental footprint, avoiding the use of harmful chemicals typically involved in metal extraction.

Fungal bioleaching, for example, has shown potential in extracting a broad spectrum of valuable metals, including nickel, vanadium, and platinum, from various solid matrices.

Microbial Partnerships: A Game Changer

The role of microorganisms in metal recycling extends beyond bioleaching. Gluconobacter bacteria, for instance, produce organic acids capable of extracting rare earth elements from spent catalysts and phosphors. This microbial method offers a greener alternative to traditional metal-leaching acids, such as hydrochloric acid, with the added benefit of natural degradation.

Although these bacterial acids might not achieve the high recovery rates of hydrochloric acid, they present a viable, eco-friendly solution for recycling rare earth elements.

Technological Innovations in Metal Sorting

Advancements in technology have revolutionized metal sorting, enhancing both efficiency and accuracy. Spectrometry-based sorting and eddy current separators now enable precise separation of various metals from mixed waste streams.

These technologies are particularly effective in identifying non-magnetic metals and separating non-ferrous metals like aluminum and copper. Additionally, infrared detection and advanced X-ray technology further refine the sorting process, ensuring high-quality recycled metal products.

The Role of IoT and Robotics in Recycling

The Internet of Things (IoT) has also made its mark on metal recycling. IoT-enabled devices, such as fill-level sensors and smart bins, optimize waste collection by monitoring container statuses and enabling timely pickups.

This integration of technology streamlines operations and enhances the recycling process’s overall efficiency. Moreover, the advent of recycling robots and chemical recycling methods like pyrolysis and gasification promises even better material recovery rates, opening new doors for the industry.

Eco-friendly Metal Recycling Practices

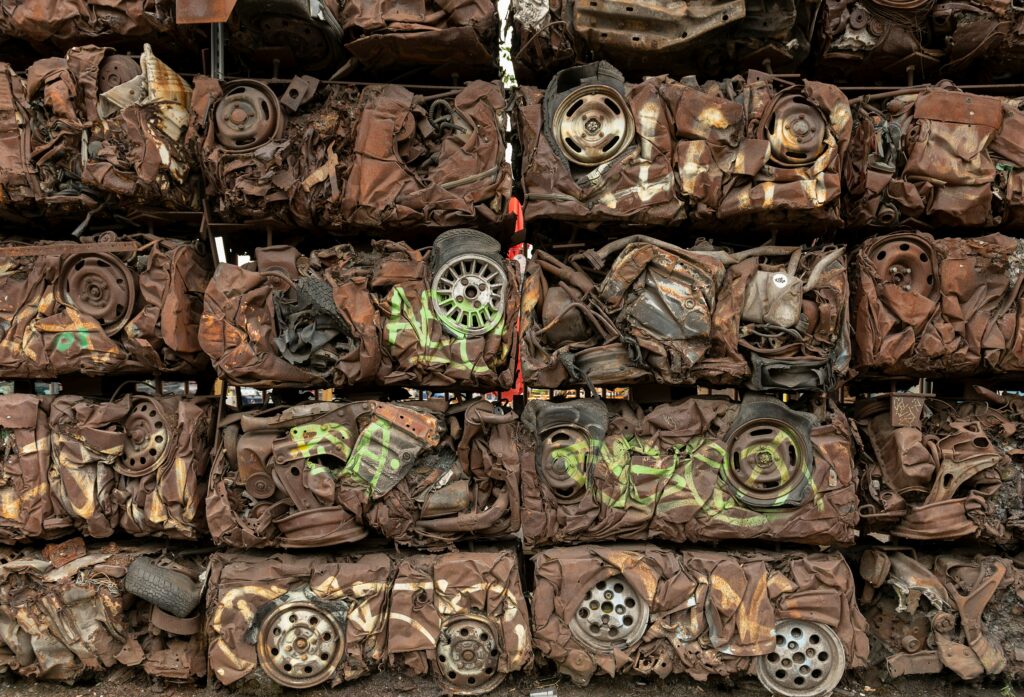

Sustainability is at the heart of modern metal recycling efforts. Eco-friendly processing methods aim to minimize the environmental impact of recycling operations. Energy-efficient melting practices, low-impact shredding techniques, and chemical-free metal purification are just a few examples of how the industry is moving towards greener practices.

These methods not only reduce energy consumption and pollution but also ensure that recycled metals are of high quality and suitable for various applications.

Case Studies: From Theory to Practice

Real-world applications of these innovative techniques highlight their potential impact. In the EU, researchers are developing low-polluting metal recovery techniques from tech waste, contributing to urban mining initiatives.

These efforts aim to reduce reliance on virgin materials and promote the reuse of metals in new products. Similarly, companies like Riverside are setting industry benchmarks with advanced sorting technologies and eco-friendly processing methods, showcasing the practical application and benefits of these innovations.

Looking Ahead: Challenges and Opportunities

Despite the promising advancements, the metal recycling industry faces challenges, including technological limitations, economic feasibility, and regulatory hurdles. However, the continued evolution of recycling technologies and the growing emphasis on sustainability suggest a bright future.

As we move forward, it’s essential to support research and development in this field, encouraging the adoption of innovative practices and technologies that can further enhance the efficiency and environmental friendliness of metal recycling.

In conclusion, the metal recycling industry is on the cusp of a revolution, driven by innovative techniques and technologies. From bioleaching to IoT-enabled waste management and eco-friendly processing methods, these advancements are not only making metal recycling more efficient but also a critical component of the circular economy.

By embracing these innovations, we can reduce our environmental footprint, conserve natural resources, and move towards a more sustainable future.